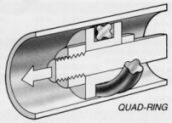

The four-lobed design provides twice the sealing surface of a comparable standard o-ring and because of this double-seal action, less squeeze is required to maintain an effective seal. This reduction in squeeze means less friction and therefore, improved seal life.

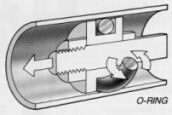

Unlike o-rings, where parting lines are on the sealing surface, QUAD-RING

seals' parting lines lie between the lobes, away from the sealing surface. This

design eliminates the problems of leakage often resulting from a parting line's

irregular surface.

QUAD-RING seals can be used as compression-type seals

in high speed rotary applications, eliminating the need for costlier

spring-loaded seals. They offer low friction for long life in hydraulic systems

with speeds of up to 900 FPM (4.5 M/Sec).