Don't see what you are looking for? Many other

products available. Please use our

quickquote form to inquire.

|

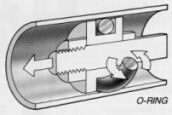

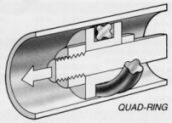

These seals are used today around the world for a wide

variety of static and dynamic sealing applications.

The four-lobed design provides twice the sealing surface

of a comparable standard o-ring and because of this

double-seal action, less squeeze is required to maintain

an effective seal. This reduction in squeeze means less

friction and therefore, improved seal life.

Unlike o-rings, where parting lines are on the sealing

surface, QUAD-RING seals' parting lines lie between the

lobes, away from the sealing surface. This design

eliminates the problems of leakage often resulting from

a parting line's irregular surface.

QUAD-RING seals can be used as compression-type seals in

high speed rotary applications, eliminating the need for

costlier spring-loaded seals. They offer low friction

for long life in hydraulic systems with speeds of up to

900 FPM (4.5 M/Sec).

|

|

|

|

|

In order to minimize breakaway friction, an o-ring groove

must be wide enough to allow rolling or twisting of the

seal. In the long stroke of a reciprocating seal

application, this twisting action can strain and finally

rupture the rubber, resulting in a type of seal failure

known as spiral twist

The QUAD-RING seal's four-lobed configuration is designed to

withstand the distortion and extrusion often caused by high

or pulsating pressure, and thus eliminates this rolling

action. As a result, a QUAD-RING seal calls for a narrower

groove cross-section than does a comparable o-ring seal.

The following sections are guidelines for the design of

QUAD-RING seal grooves for both rotary and non-rotary

applications. |

|

|

|

|

|

|

Information Provided by Minnesota Rubber/Quadion Corporation, copyright

2002

Product names are

Registered trademarks of Minnesota Rubber, A Quadion Company.

|